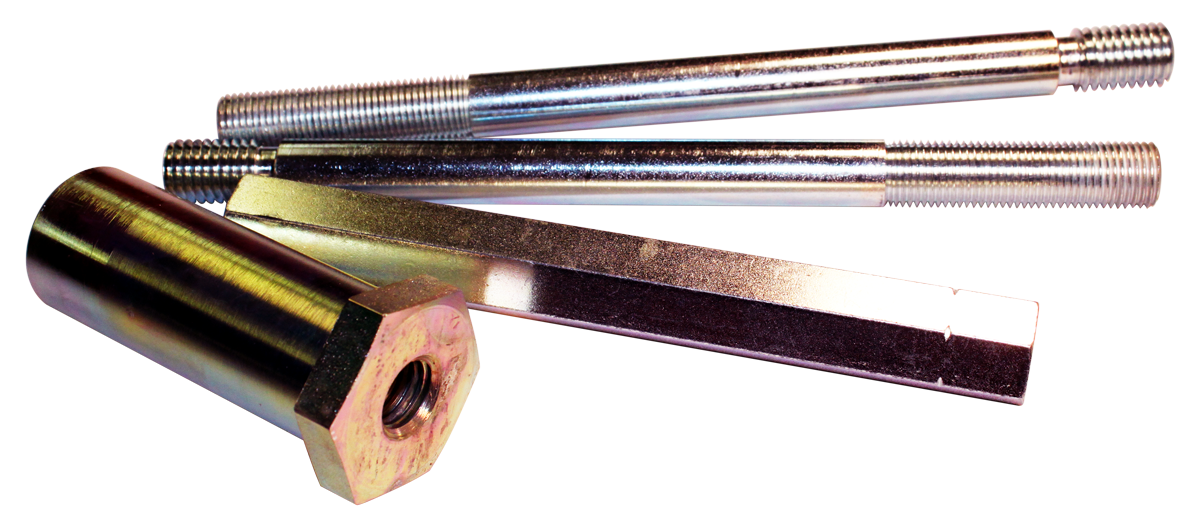

CNC Machining

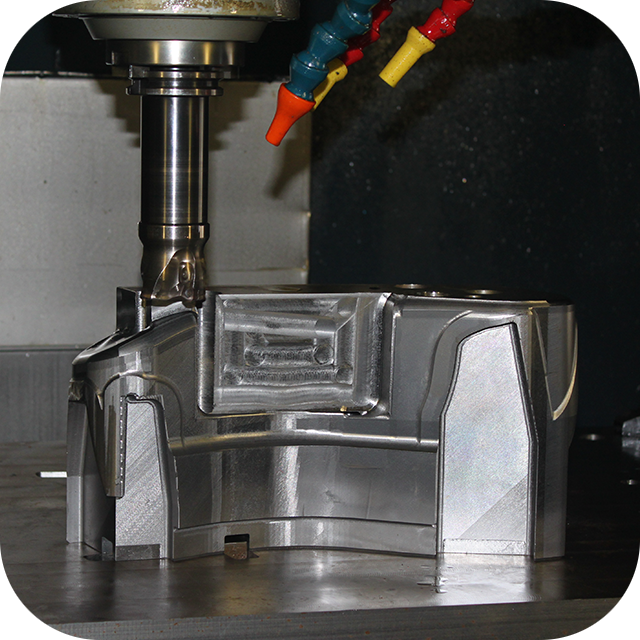

Our CNC Milling & Turning department excels in crafting a diverse range of tooling and specialized components with precision. We leverage advanced surfacing techniques to streamline polishing and preparation processes, optimizing tooling performance both before coating applications and after heat treatment.

With our in-house tool design and CNC programming expertise, we deliver cost-effective, high-quality solutions with rapid turnaround times, tailored to meet our customers' unique needs.

CNC Milling Equipment

- 2× Johnford SL-500 Lathe - 10" Chuck

- SMEC MCV5500 Vertical Machining Center · 41" × 21" × 20"

- Fanuc Robodrill D21MiA5-10k · 19.7" × 15.7" × 13"

- Fanuc Robodrill D21LiA5-10k · 27.6" × 15.7" × 13"

- Fanuc Robodrill D21LiB5-10k · 27.6" × 15.7" × 13"

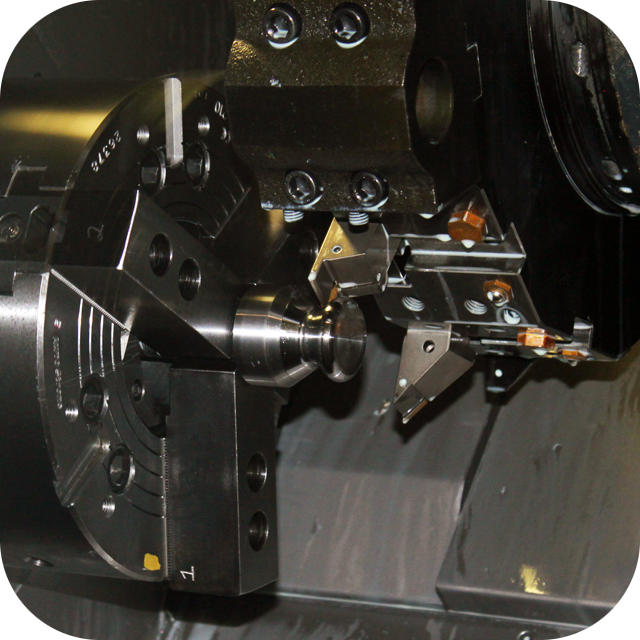

CNC Lathe Equipment

- Eurotech Elite E42SL · Sub-Spindle / Live Tooling

- Eurotech Elite 735SL-Y · Sub-Spindle / Live Tooling Y-axis

- Eurotech Elite 545SL-Y · Sub-Spindle / Live Tooling Y-axis

- 2× Johnford SL-500 Lathe · 10" Chuck

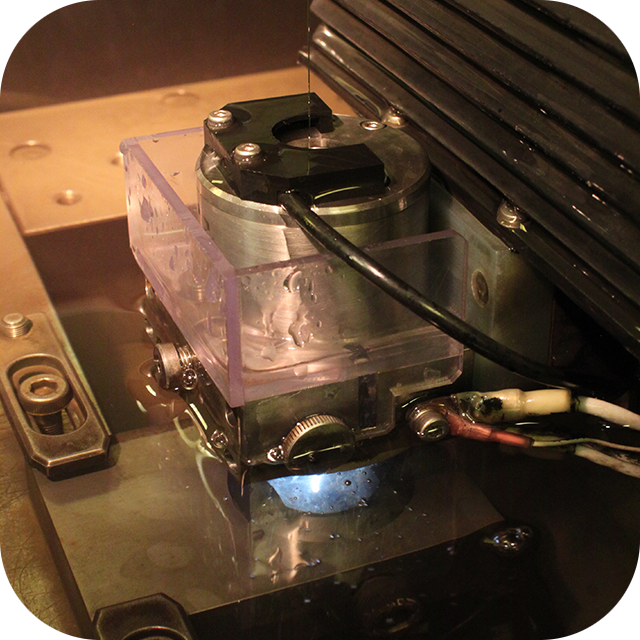

EDM [Electrical Discharge Machining]

We use our EDM capabilities to perform both stand-alone tasks and finishing operations in tooling projects that require superior accuracy and surface-finish quality. Our use of Wire EDM in conjunction with CNC Machining also allows us to provide economical and timely solutions and focus on the specific needs of each project for our customers.

EDM Equipment

- Fanuc C600iA-12" Wire EDM · 23.6" × 15.7" × 12.2"

- Fanuc 0iC-10" Wire EDM Machine · 12.6" × 8.7" × 10"

Manual Machining

We use our in-house manual machining equipment to prepare tooling for the CNC machines. As a result, we are able to perform CNC machining with increased flexibility and efficiency.

Our experienced, full-time staff of manual machinists is dedicated to the completion of projects ranging from the smallest and simplest of manual-machining tasks to the largest and most complex of fabrications and assemblies.

Manual Machining Equipment

- 2 · Bridgeport Vertical Milling Machine · 9" × 42" (DRO)

- 4 · Sharp Vertical Milling Machine · 10" × 50" (DRO)

- Cincinnati Vertical Milling Machine · 16" × 70" (DRO)

- Greaves Horizontal Milling Machine · 28" × 12" × 20"

- Ikeda 4" Arm - 10" Column-Radial Drill Press

- Fosdick Drill Press - 24" × 36" Table

Finishing & Grinding Equipment

- Sharp - 12" x 24" Hydraulic Surface Grinder

- Sharp - 16" x 32" Hydraulic Surface Grinder

- Supertec - 6" x 18" Surface Grinder

- Sunnen LBA666 Honing Machine

Welding Equipment

- Miller Synchrowave 250DX - TIG and Stick

- Millermatic 252 MIG

- Miller Spectrum 2050 Plasma Cutter

- Hobart Handler 140 MIG

Production Machining

Order more when you need it, and we'll keep it here in stock for you.

Start a production machining relationship with us and get quick access and lower costs on conventional and multi-access CNC machining, wire EDM, vacuum heat treating, milling, assembly, and more.