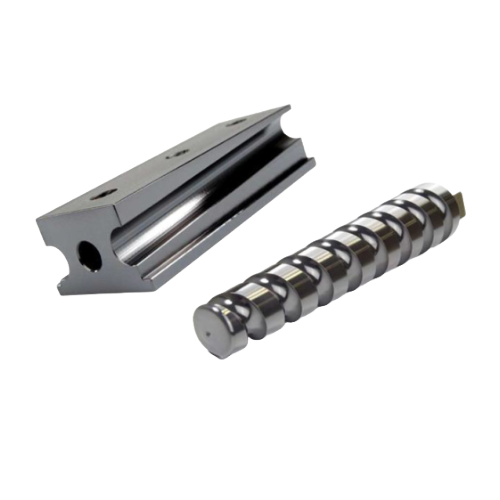

Tool-Dynamics provides a wide range of advanced coatings designed to enhance protection and extend the lifespan of your tooling.

Below, you will find a list of coatings and basic applications that we offer in house. You can submit a RFQ by clicking that link and uploading the request directly to us or if you have questions, fill out the process sheet and contact one of our skilled sales representatives with your questions.

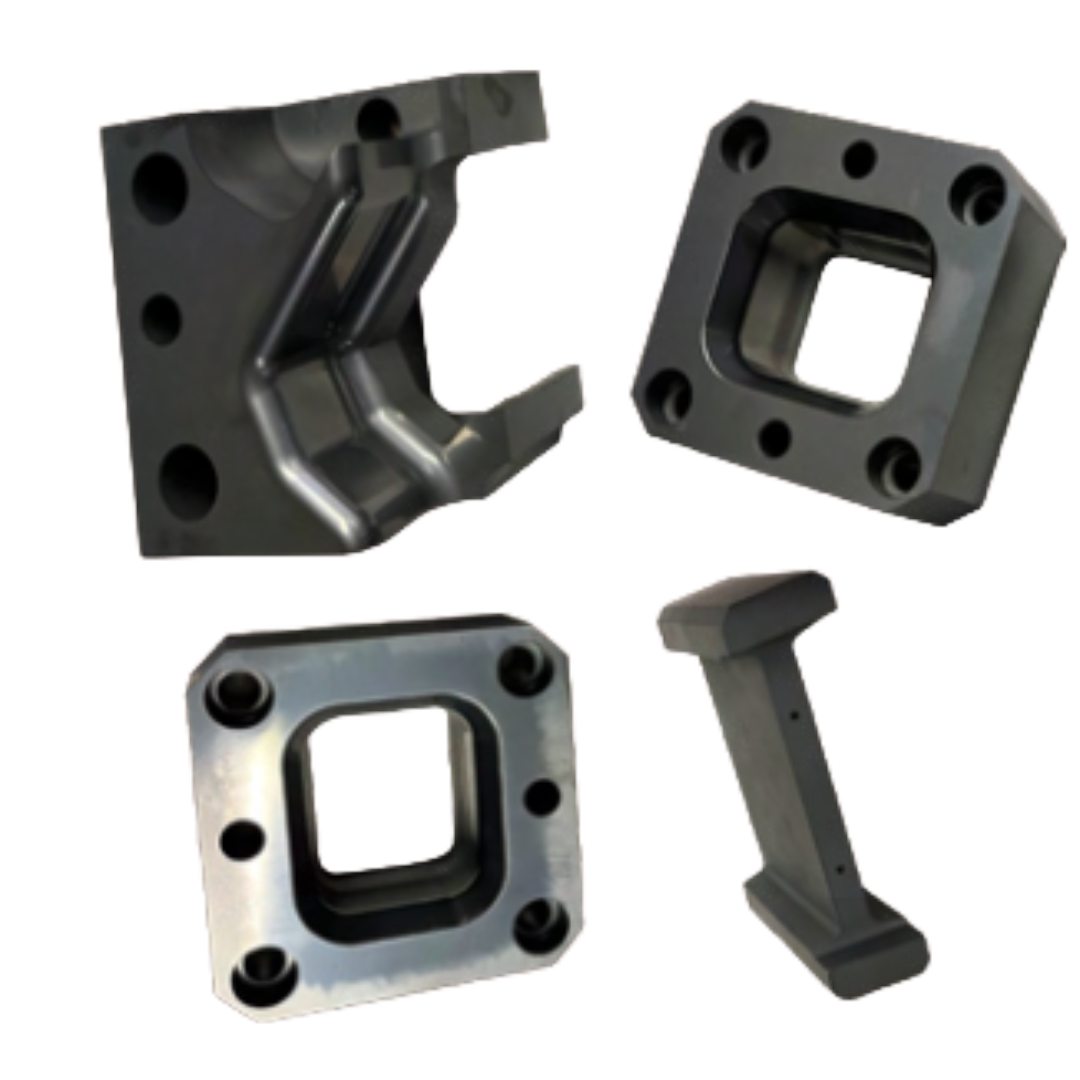

TDX Coating

TDX coating is the long-recognized industry standard for high-pressure forming applications.

The combination of a hot-process metallurgical bond with a super-hard layer of carbide has made TDX the choice coating for difficult applications such as stainless steel, HSLA, thick material, and draw-die applications with high material flow. This surface has 4200 Vickers hardness with high adhesion strength and peel resistance.

TDX Physical Properties:

- Hardness: 4200 Vickers

- Co-efficient of Friction: 0.4

- Operating Temperature: 2000°

- Thickness: 4-5µ (microns)

Good TDX Applications:

- High Strength Materials (HSLA) Stamping

- Stainless-Steel Stamping

- Hydroforming

- Roll Forming

- Extrusion

- Tube Forming

- Piercing / Trim Details

- Cold Forging

- Form Punches

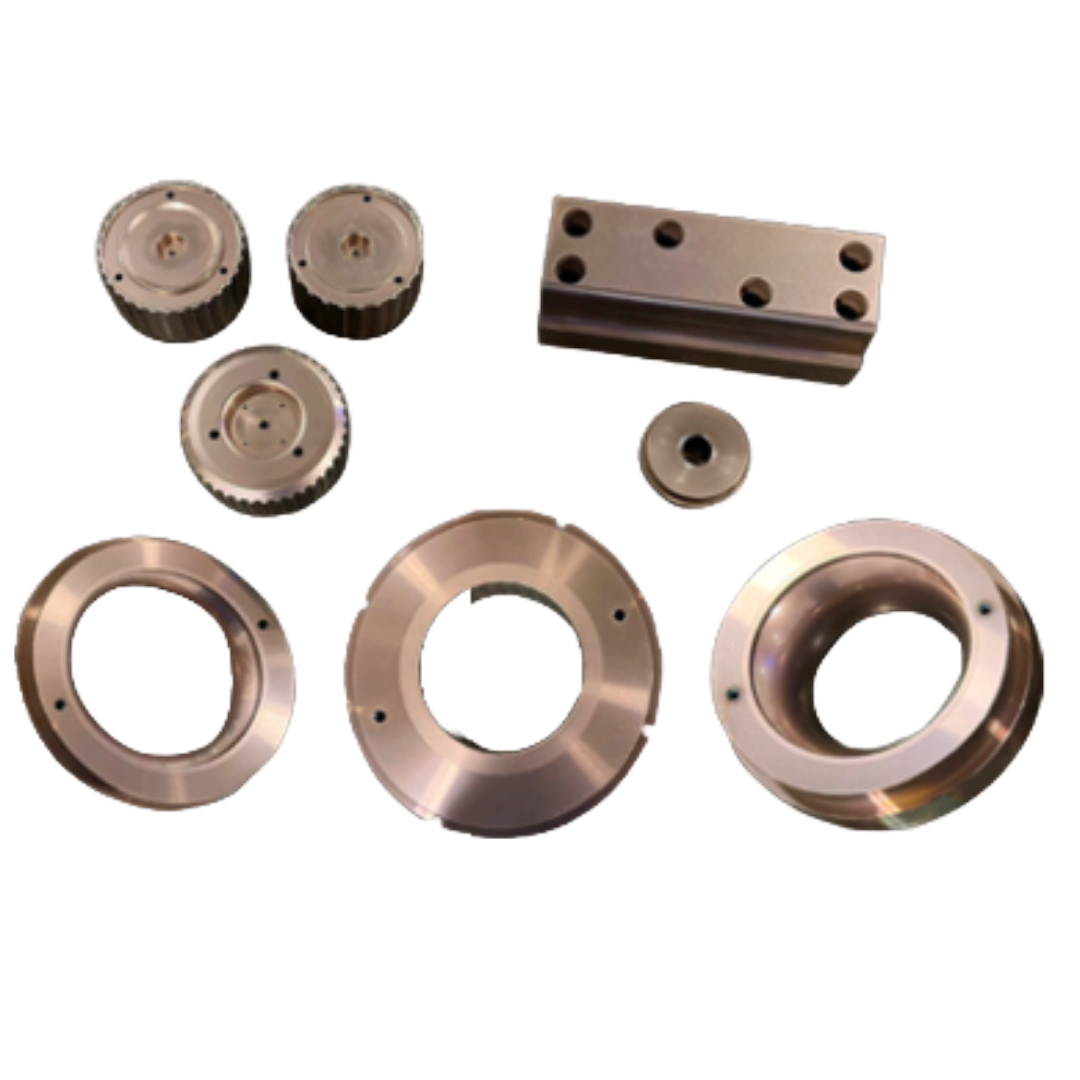

PVD Coating

PVD (Physical Vapor Deposition) coatings are great for tightly toleranced details.

When a more durable but very hot process such as TDX cannot be used, PVD is the colder, more precise answer.

Tool-Dynamics offers two types of PVD coatings that include: FormX and CRX.

FormX

FormX is offered multilayered coating including TIN, TIALN, and TICN

FormX Physical Properties:

FormX Applications:

CRX

CRX Physical Properties:

- Hardness: 3300 Vickers

- Co-efficient of Friction: 0.4

- Operating Temperature: 2000°

- Thickness: 4-5µ (microns)

CRX Applications:

- Cut-off Blades

- Hot Stamping

- Trim Tooling

- Die Cast Tooling

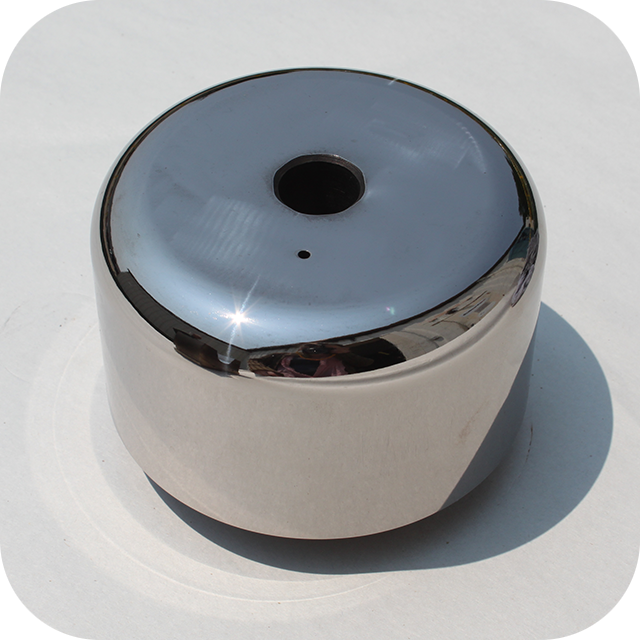

DLCX

DLCX Physical Properties:

- Hardness: 1000+/-300

- Co-efficient of Frictions: 0.2

- Operating Temperature: 177°F

- Thickness: ≥3µ (microns)

- Color: Black/Grey

DLCX Applications:

- Forming and Blanking Dies For Non-ferrous materials

- Plastic Injections Molding Dies

- Sliding Parts

- Machine Componets

- Other Cutting applications of aluminum with low Si-content